Schedule May 2008

return to main 1401 Restoration Page

go to Team Bios

Contents:

Mon May 05 - Connecticut 1401 arrived,

Wed May 07 - cabling, power supplies,

Sat May 10 - class visit,

Wed May 14 - general,

Wed May 21 - general,

Wed May 28 - general,

Mon May 05 - Connecticut 1401 arrived,

Unloading the BIG truck

Moving other things from the loading dock to Allison's "staging area" - documents, spare SMS cards, extras

And, back in the 1401 restoration area -

Wed May 7 - cabling, power supplies

Sat May 10 - class visit

Wed May 14 - general

Wed May 21 - General

Wed May 28 - general

Background, Robert Garner and Frank King packaged and helped extract and load the CT 1401

here.

Frank checking if the stuck wheel would now rotate, it would :-))

The Connecticut 1401 in its new home.

Another printer, crossing that tooth jarring, shock testing steel mat

And the 1402 reader-punch is unveiled :-)) Not a scratch or dent :-))

Great Move! Time to sign off !! Jeff the van driver with Robert Garner. IBM is footing the moving bill :-))

Off the truck, into "InVisible" Storage

A-Rollin along - a box of spare cables, and a box of spare SMS cards

Don't we have a lovely environment?

Off the dollies, onto pallets, and checking what's in 'em

Towards the end of a long exciting day, opening, unpacking, deciding, grouping, ...

Ed likes to be near the critical path, to stay hired, but works hard to keep off the critical path,

to sleep easily and have fun ;-))

a) applied WD-40 and motion to free up the latch

b) rebent a bent bottom support

c) and re-adjusted and unbent the catch

Then noticed that the loading window was taped to stay up, but would not stay up.

Then I went to the next drive in the line, second from north - and the loading window was stuck up.

It would hit something hard when lowered about 1/4 inch

The protective metal has been removed from the window supports. Both cables broken, at least one spring broken.

Details of right side support

More details

Missing interlock activator clip

Load window hardware seems good

but there is a problem here.

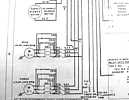

My those are long cables, nice that they are clean.

Cables toward the 1403 printer - we did not connect any end points such as the 1402 and 1406.

End of a long day, lookin good :-))

"Our" software group leader, (Dr.) Ron Mak,

originator of ROPE, author of

20 Lessons Learned from NASAs Mars Exploration Rover Mission,

brought his Santa Clara University class to CHM, and our 1401 restoration :-))

With Bill Worthington

in Visible Storage

With Dave Cortesi

in 1401 Restoration

What a puzzle - Stan came by so I watched motor voltages and heating (back side of 1402)

and he worked on the relay,

fuses, and other circuity (front side).

Ron Williams and Bob Feretich checked that the all fans rotated - yes - but the rundown time is quite short,

Probably a good plan to disassemble and lubricate them all -

Frank King began checking his new 1403 printer -

Planned "All Hands Meeting" postponed until late June -

Allison Akbay and William Harnack (left) of the Registrar's function came by to measure and record some

of the units and serial numbers -

Billie Dungan and Reginald W. Oldershaw came by. Reggie had worked at Ampex (about 5 miles away)

starting about 1967. I had fought with

Ampex tape drives about 1961 -

and we had some laughs together. (He seems to have some patents.)

It was a mighty struggle between two stubborn men and one stubborn beast !!

And you thought mules have a reputation !!!

This involves punching securing holes in the Kapton ribbon exactly correctly so there is no slack,

threading the thin ribbon through the thin magnetic gaps of 34 hammers/section,

hot gluing the ribbon ends over the hooks to assure permanence, and takes

patience and fortitude -

The job ain't done until the paper work's complete ;-))