Schedule January 2006

return to main 1401 Restoration Page

go to February 2006

Contents:

Wednesday January 4th

Wednesday January 11th

Saturday January 14th

Wednesday January 18th

Wednesday January 25th

No electric power in building Wednesday Jan 24th - meeting canceled - see you Saturday

Saturday January 28th

- Wednesday January 4th - 10 AM - Roll up sleeves -

Present were Glen Lea, Ron Williams, Bob Erickson, Don Cull, Ron Crane, Bill Flora, Grant Saviers and Ed Thelen. Soon Jeff Stutzman joined us. Jeff knows Ron Crane and was curious about our efforts. There were lots of folks, and we also had a big day :-)) Where to start?

We took a trip to deep storage with Chris Garcia to examine a newly donated IBM 085 collator, and put on the skins as requested by Allison Akbay, CHM Registrar.

First, apologies, Bill Flora & Don Cull worked on the punch of the 1402 ReaderPunch - and I have no idea what they did - they were using the 1401 to send commands to the punch.

Bob Erickson Glen Lea are disassembling the 077 collator to further examine the high friction problem. (The 1/4 horse motor could not bring the machine up to full speed as reported last week.) Later they were joined by a photographer from the Palo Alto Times doing an article on Len Shustek and Donna Dubinsky - members of the CHM Board of Trustees.

Grant Saviers brought in an ultrasonic cleaning machine to aid in cleaning many items. Here he is cleaning a shaft from the 077 collator above. The blue thing is a tooth brush - handy!!

The 077 collator has lots of shafts to help guide and propel cards along the card path.

The second image shows where a needle bearing has failed. The needles apparently seized and wore the hardened steel shaft to a much smaller diameter. There was another seized needle bearing. Grant Saviers is thinking about how to fix these situations. Grant's 077 bearing report

Ron Williams, Ed Thelen & Jeff Stutzman worked on making replacement Strip Residuals from 2 mil magnetic tape instead of 3 mil mylar which we could not find yet.

The Strip Residuals (name from 1403 Maintenance Book) prevents Hammer Armature from contacting rest of electromagnet and possibly sticking from residual magnetism.

The guy on the ladder is Dave Dial, new Vice President of Operations -this is my best picture as he was either on the roof checking odd situations or had head in overhead.

The man under the ladder is Ron Crane, a circuits guy who likes nanowatts to kilowatts. His and Dave's efforts will likely save the museum over $20,000 / year in electric power billing. They identified a roof mounted 10 Hp? squirrel cage blower that a) was wired backward, b) blowing into a duct that was taped shut. - Disabling this useless situation will save the museum $18/week or $7,000/year. And there is a lot more to go. They think they can eliminate the need for the very noisy Liebert airconditioners :-))) Ron Crane Report and Ron Crane Power Sept 2005

Amendments - by individuals noted

Bob Erickson wrote (Jan 5th)

Grant Saviers wrote (Jan 6th)Hi Grant,

Sit down and hang onto your hat. After you had gone we removed the first feed roll from the primary feed and the needle bearings on it are worn the same way, maybe a little worse. So maybe we should think about taking our replacement parts from one of the two other machines that we have, There is an 077 in visual storage and an 085 that just came in, I believe all the first feedrolls are the same, so hold off on making repairs to the roll you have until after next wednesday.

Thats all I can tell you right now.

Thanks for your help.

Bob

Grant Saviers wrote (Jan 7th)

Bob,

Ok, although I've ordered the bearing stock ($9). Fixing several of these, once the design and process is thought through and fixturing built is pretty easy.

I measured the feed roll I have and produced a drawing, attached in pdf form. 11 KiloBytes I'm learning a new CAD package so niceties like hidden lines aren't yet in my skill set.

You can quickly check the other shafts with the dial caliper is the 1401 room to see if they are the same.

- Wednesday January 11th - 10 AM - Roll up sleeves -

Present were Bob Erickson, Jeff Stutzman, Chuck Kantman, Ron Williams, Bill Flora, Allen Palmer, Frank King, Bob Feretich, Robert Garner, Ron Crane and Ed Thelen. Lots of action.

The printer seemed somewhat out of alignment. (Shipping, aging, and new gaps due to new "Strip Residuals" will do that. This is somewhat improved. Column 131 seemed erratic - what is going on???

And this is how you adjust the horizontal position of individual characters. First and foremost, the hammer must strike the character slug at the right time so that all of the character is hit by the hammer. "H" is a good test character as it has both sided to be printed. Next, you should fine adjust so that the characters seem evenly spaced. The wood handled tool has an eccentric cylinder on the tip, to move something inside the individual hammer assembly. The long handled screwdriver releases and tightens the clamping mechanism to keep the adjustment fixed.

Are we making progress? Hmmmm

After a long period of adjustments, and frustration with column 131 - there was the unmistakable aroma of overheated insulation. The solenoid coil of hammer 131 was blackening!! The resistance of coil 131 was found to be 2 ohms rather than the nominal 8 ohms!!! OOPS - an internal short between 2 windings? Here Ron Crane is trying to remove the 85 mil connector pins (so we can replace with a spare coil) and we don't have the proper (standard) tool - well, maybe next time.

David Macklin came through the Visible Storage tour, and Harlin Snyder brought his group to visit us. It turns out that David Macklin headed the group of three that

did the upgrades to make the 1401 assembler SPS 2 & 3

designed and led the group to make the 1401 AutoCoder Assembler (more free form :-))

led the group to make the 1401 FORTRAN,

- which could compile and run on a 4000 character memory 1401

- with maybe 63 overlays or phases and a paper describing the "phases"

of course you could compile and execute more on a larger machine.

And the sick bearing and shafts of the 077 collator. Dag Spicer gave us permission to examine the 077 in Visible Storage. OK - so this is a newer generation machine. The needle bearings have been replaced with sintered bronze bearings, and a lubrication system installed to assure long life.

Here is the oil pump and an authentic power supply. The power supply in "our" 077 is definitely an emergency substitution of a power supply designed for another use.

- Saturday January 14th - 10 AM - Roll up sleeves -

Present were Bob Erickson, Ron Williams, Tim Coslet and Ed Thelen.

- Bob Erickson continued working on 077 collator. cleaning shafts, bearing, ... with ultrasonic cleaner.

- Tim Coslet brought his incircuit test set up and found 2 bad 033 transistors on the failed hammer driver card. One transistor yielded a wild figure 8 voltage-to-current curve that shifted with time - We had the replacement 2N1303 transistors :-))

- Ron Williams got three more instructions going. He wouldn't tell me what they were claiming that if he has a bad debug session - he has some reserves hidden away - and you thought only accountants cooked the books !! ;-))

- We noticed that the magnetic tape emergency "Strip Residuals" (- see Jan 11th ) had apparently charred in the magnetic gaps of the print hammer solenoids. Weird!! The coils and iron shouldn't get that hot under the low duty cycling last Wednesday.

- Ed Thelen and Ron Williams cut some of Frank King's "Cutone" 3 mil plastic into 1/2 inch strips using the half inch grid of a paper cutter base to replace the mag tape "Strip Residuals" .

- Ed Thelen then glued the strips into the 1403 as a temporary measure to see what happens. Will there be blackening and or wear?

Added Tuesday, Jan 17

- Bob Feretich is confident that the 1402 controller, which he and Ron Williams debugged in this bring up - does not have the Binary Read optinal feature. "I saw nothing in the logic diagrams that indicated it had the feature. If it does, then the column binary feature must be almost completely independent of the main reader logic."

Somebody was asking for the IBM 1401 Special Feature Instruction ManualAdded in February

To replace the defective printer column 131 hammer solonoid, Ron used our only spare solenoid coil from his CE friend Phil Clark (Thanks Phil!).

- Wednesday January 18th - 10 AM - Roll up sleeves -

Folks - did we ever have a fun day!! Present were Bob Erickson, Ron Williams, Jeff Stutzman, Glenn Lea, Frank King, Allen Palmer, Grant Saviers, Ron Crane, Robert Garner, Robert Feretich, Bill Flora, and Ed Thelen. We also had shorter visits from Dave Bennet, Randy Neff, Bill Selmeier, Harlin Snyder, several tour groups, and a TV crew from "france 2". And we even got stuff done !! :-))

Bill Selmeier took a movie of the action "... IBM 1401 they have been restoring to print. Posted on his web page.

Dear Folks - the 1403 printer appears functional !!

Frank King wants to make sure that we don't run any "break the chain" programs. He said that some folks wrote print routines that were intended to maximally stress the "chain". The "links" of the print chain are held together with a plastic band (that seems to have glass fibers? length wise in it?). Other plastic in the printer - such as the "Strip Residuals" - have not done well over the last 45 years, and Frank does not want to break this plastic band either. Frank wishes to point out that playing "music" programs on the 1403 printer was a very infrequent event in the old days - and he wishes to keep it infrequent!Many people pitched in to help with many things - name assignments do not mean that others did not help - "Many hands make light work." And indeed "work" seemed very easy today.

- Printer Pictures

- Movie of 1403 printing successive powers of 2 1.8 megabytes - compressed by Bill Selemeier :-))

- Frank and Ed went into Deep Deep Storage ;-)) to get the sound absorbing cover for the 1403 printer. Allison Akbay, William Harnack, and an intern were Registraring - and came back to the 1401 with us to help celebrate the printer :-))

- Tape unit operations

- Bill Flora, Robert Garner and others worked on the 1402 Reader Side - replacing the dynamic timing unit which has long been a thorn. Repeated attempts to get it to work well have failed - They removed the dynamic timing unit from the 1402 in Visible Storage and installed it in this machine.

- Bob Erickson and I (Ed Thelen) (with Dag's permission) moved the 077 collator from Visible Storage into the 1401 Restoration to better swap some badly damaged feed rollers. This work is proceeding quickly so that there will soon be a 077 collator back in visible storage. The unit from Visible Storage has the original power supply - with selenium rectifier yet :-| Bob says it is not illegal to power selenium rectifiers due to potential dangerous outgassing if the unit is overdriven (shorted).

- We had so many people talking and so much equipment energized, that the room got warm and someone turned on the Liebert air conditioner for a while :-(

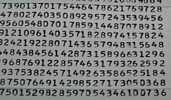

Santa - Give me new eyes - or larger print - Ron Williams examining a ... hmmm ... I can't see it either

Laura Tenoudji, TV journalist from "france 2" - Ed Thelen is - well, Allen says "don't tell Betty" ;-))

- Wednesday January 25th - 10 AM - Roll up sleeves -

No electric power in building Wednesday Jan 24th - meeting canceled - see you Saturday

- Saturday January 28th - 10 AM - Roll up sleeves -

Present were Ron Williams, Bill Flora, Bob Erickson, Tim Coslet, Robert Garner and Ed Thelen.

- But, of course, since we're still getting read checks and spuriously reading incorrectly, there's still something wrong with the 1402 interface, which Ron and Bill worked on most of the afternoon.

-

Life has its embarrasing moments. One occured to Bob Erickson. He was holding this 077 shaft at a slight angle, and most of the bearing and separators just plain slid off. - -

Bob Erickson and Tim Coslet enjoying near the Visible Storage 077 Collator.

- Wednesday January 11th - 10 AM - Roll up sleeves -

go to February 2006