After working for G.E. and CDC, for about 5 years each, I worked for 17 years

for Measurex - a paper process control company :-)) Measurex has since disappeared

into the maw of another corporation :-((

We leased our

process control scanners, gauges, and software to paper companies to help

them control their paper making machinery.

If you ever get a chance

to visit a paper mill

- jump - it is unbelievable - HUGE equipment -

- - - YouTube (Wisconsin),

- - - another slow start, more complete

- - - and another

(British) has a slow start, shows Measurex control display and later a scanning gauge on-sheet

Wikipedia now has a

rather good description -

A quick overview

- a huge pressurized "head box" up to say 10 meters wide with tons of thin (wood pulp) mush

- continually being refreshed from a 16 inch pipe from ...

- with paddles to gently keep the mush uniform

- a thin ribbon of the thin (wood pulp) mush, 10 meters wide, from the head box

- streaming at up to 60 miles per hour - 1500 meters/minute

- on to a "wire" screen belt say 11 meters wide and 30 meter long moving at the same speed

to drain and vacuum out as much water as practical

- to the cooch roll, to squeeze and vacuum out as much more water as practical

- through huge drying sections say 75 meters long and 4 stories high

with huge steam heated drums which dry the paper to about 6% moisture,

- through or past the calender stack depending of requirements

- to huge take up rolls that accumulate about 10 tons of paper each,

- when full an empty roll magically begins to accumulate the streaming paper.

(Roland Sundstrand has kindly updated some of the above numbers. :-))

The same equipment (in general) (but with different pulp recipes and machine settings) can make news print, paper for books and magazines,

and - ta ta - IBM Punched Card stock. (IBM cut it into cards and printed on it.)

However, two kinds of paper used to give paper makers fits - very difficult to make spec -

- Xerox paper

- IBM Punched Card stock

Although technology now helps measure and control some parameters,

Papermaking is still very much an industrial art.

The paper makers on the machine are union members,

*but* get paid by the ton of on spec paper! Serious, thoughtful, alert, cooperative work!

This is not a paper makng lesson - a fascinating field in its own right.

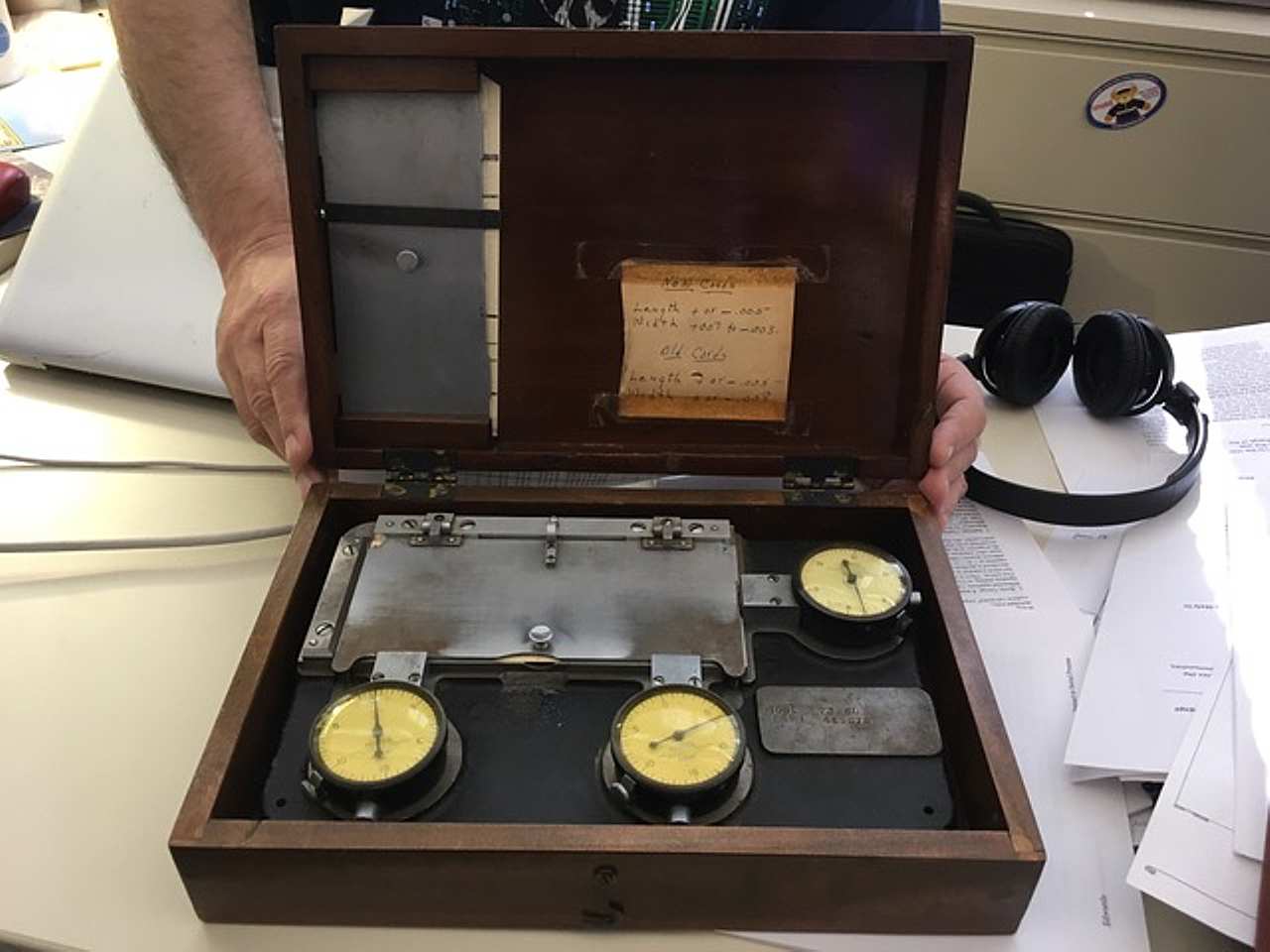

The following are the specifications that IBM insisted paper makers meet.

Fail to meet spec on what you ship,

and your freight car(s) of multiple 10 ton rolls of card stock are returned to you :-((

- with you owing freight each way :-((